Reliable, Clean Power Solutions for Chemical Manufacturing

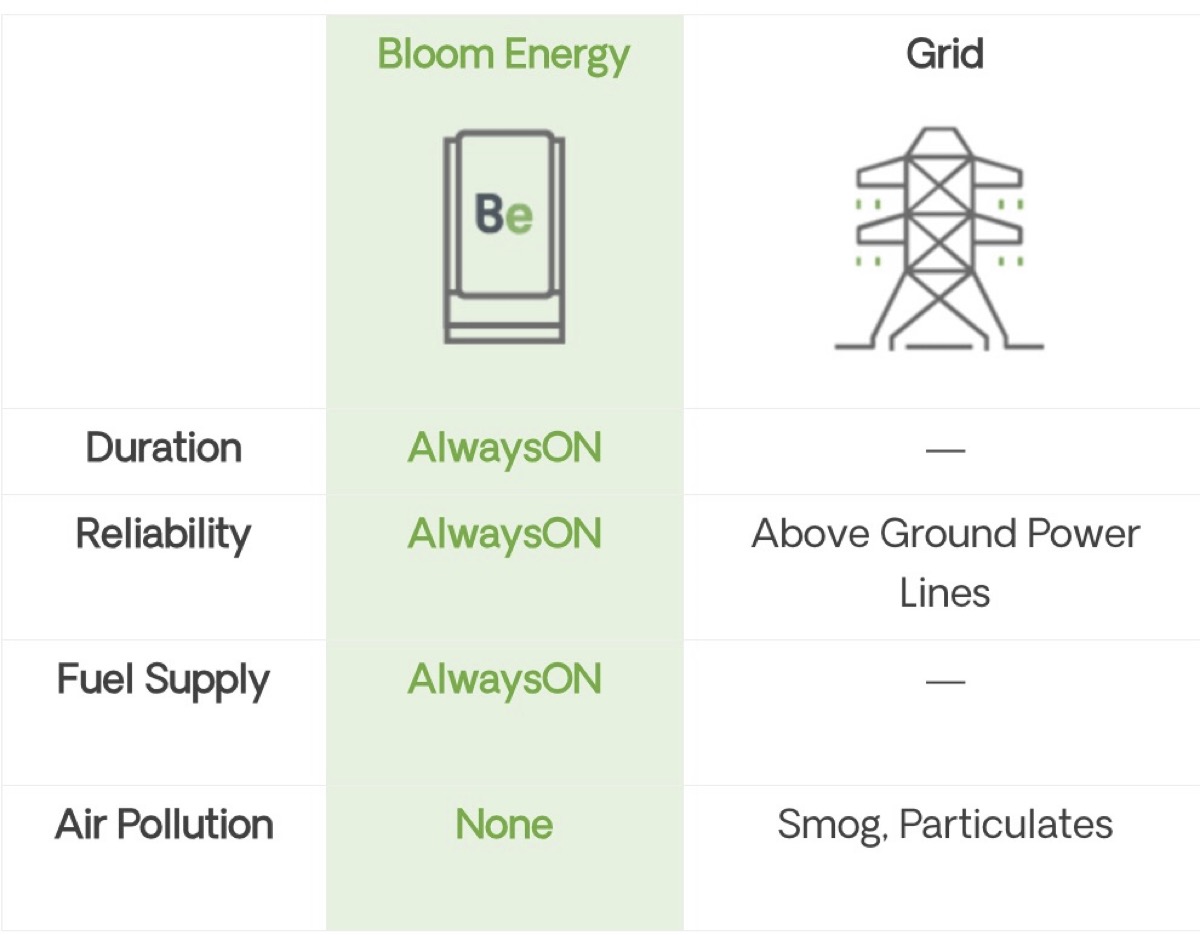

For the key priorities of chemical manufacturers, Bloom Energy’s solution is unmatched. Bloom is a trusted mission-critical partner, with more than 100 microgrid installations across the country delivering highly reliable, clean, AlwaysON power.

Chemical Manufacturing Industry at a Glance

Chemical manufacturers are large energy consumers whose operations and processes depend on available, reliable, high-quality power.

Base loads are designed to run 24/7/365 to protect and maintain delicate chemical processes occurring at the plant.

Safety is the #1 concern for plant operators, further driving the need for a highly resilient solution that mitigates risk and prevents any unplanned downtime that may put employees at risk.

Quick Facts About Chemicals Manufacturing

Overcoming Energy Challenges

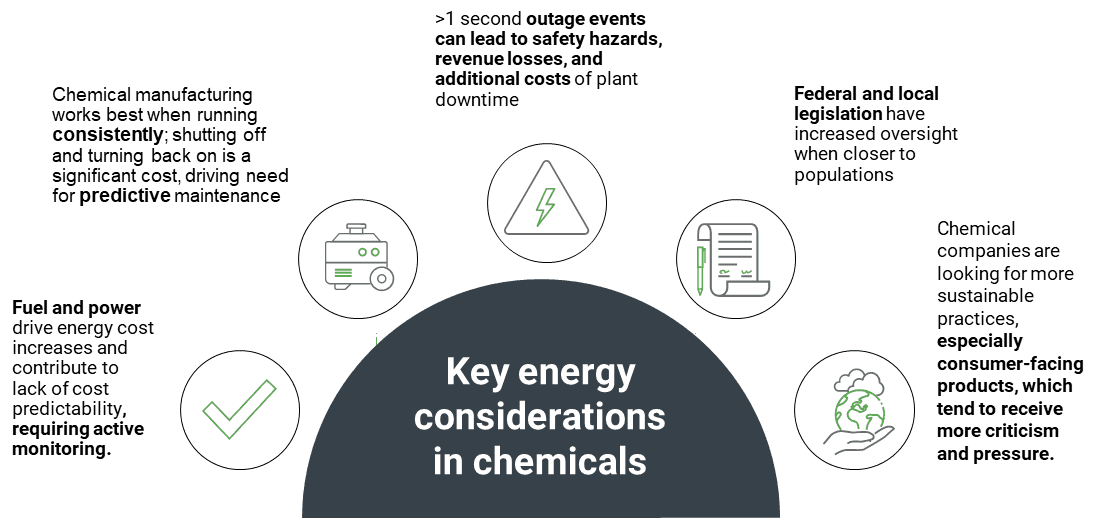

Key considerations in chemical manufacturing

Why On-Site Power and Microgrids Are Essential for Chemical Manufacturing Power Reliability

In the chemical manufacturing industry, reliable power is not just a convenience—it’s a necessity. Power interruptions can disrupt production, compromise safety, and lead to costly downtime.

By integrating renewable energy sources and carbon capture capabilities, microgrids powered by Bloom Energy Servers provide a pathway to achieving operational excellence and decarbonization. Microgrids offer advanced energy solutions for chemical plants, providing unmatched reliability, operational flexibility, and sustainability.

Key Features of Microgrids Powered by Bloom Energy Servers

1. Unmatched Power Reliability for Continuous Operations

- Deliver up to 99.999% reliability, ensuring uninterrupted power for critical processes in chemical plants.

- Microgrids provide on-site industrial power solutions, delivering maximum uptime to ensure 24/7 operations without reliance on external power grids.

2. Resilience Against Power Disruptions

- Designed with no single point of failure, ensuring consistent power even during unexpected system component issues.

- Redundant system architecture allows for maintenance without disrupting operations.

3. Independent Operation from the Grid

- Microgrids operate as self-contained systems, shielding your chemical manufacturing plant from grid instability, such as outages, voltage sags, or harmonic distortion.

- System components work in parallel, maintaining reliable power under all conditions.

4. Sustainable and Renewable Energy Integration

- Bloom Energy’s microgrids can utilize biogas, a fully renewable energy source derived from organic materials, reducing reliance on fossil fuels.

- Supports the development of green energy infrastructure, aligning with ESG and sustainability objectives.

5. Proactive Maintenance and 24/7 Monitoring

- Manned operation centers in California and India ensure round-the-clock monitoring for your microgrid system.

- Maintenance is performed without downtime, ensuring true Always-On power for your chemical factory operations.

6. Fixed Costs with Minimal Maintenance

- Fixed Operations and Maintenance costs provide budget predictability over the system’s 10 to 20-year lifespan.

- Requires minimal maintenance compared to traditional rotating equipment, reducing the operational workload of plant teams.

Chemical Manufacturing FAQs

What does chemical manufacturing do?

What are the 7 types of chemical industries?

The chemical industry is diverse, with several key segments. The seven main types of chemical industries include:

- Basic Chemicals: Produces essential chemicals like acids, bases, and salts.

- Petrochemicals: Derived from petroleum and natural gas, used to create plastics and resins.

- Specialty Chemicals: Includes products like dyes, adhesives, and coatings for specific applications.

- Agricultural Chemicals: Encompasses fertilizers, pesticides, and other agrochemicals for crop protection.

- Pharmaceuticals: Focuses on creating medications and health-related products.

- Consumer Products: These include chemicals found in personal care items, cleaning products, and cosmetics.

- Biotechnology: Uses biological processes for the production of chemicals and materials, often overlapping with agriscience and industrial biotechnology.