The massive blackouts that blanketed California in October cut power to more than 100,000 businesses. Hospital chains Sutter Health and Adventist Health were forced to cancel procedures and close facilities. Some Trader Joe’s and other supermarkets shuttered for days. Factories scrambled to find backup generators and fuel to run them.

It’s too soon to say how much these planned outages cost the economy. Energy economists are still crunching the numbers for impacts. However, at least one early figure suggests the pain was widespread. Stanford University professor and energy expert Michael Wara estimated that just one of the outages, which began on Oct. 7 and impacted 800,000 Northern California customers, would cost small commercial and industrial businesses that lie within the rural and suburban blackout zones $2.4 billion over a 48-hour period.

That didn’t have to happen. There’s an alternative to the utility-operated grids whose fragility has led to the outages. But microgrids, self-contained energy systems that can operate alongside a main grid or independently during a blackout, haven’t taken off, even though they can help businesses and communities avoid costly power interruptions like those in California.

The reason, experts say, is a combination of regulatory, financial, and technical challenges.

That, however, may soon change. As corporate financial decision-makers confront multiday outages, and their impact on the workforce and on business continuity, they could begin adopting microgrids at a rapid pace, says Peter Asmus, who studies energy generation for Navigant Research. “My sense is microgrids are going to take off,” he says.

A look at microgrid options

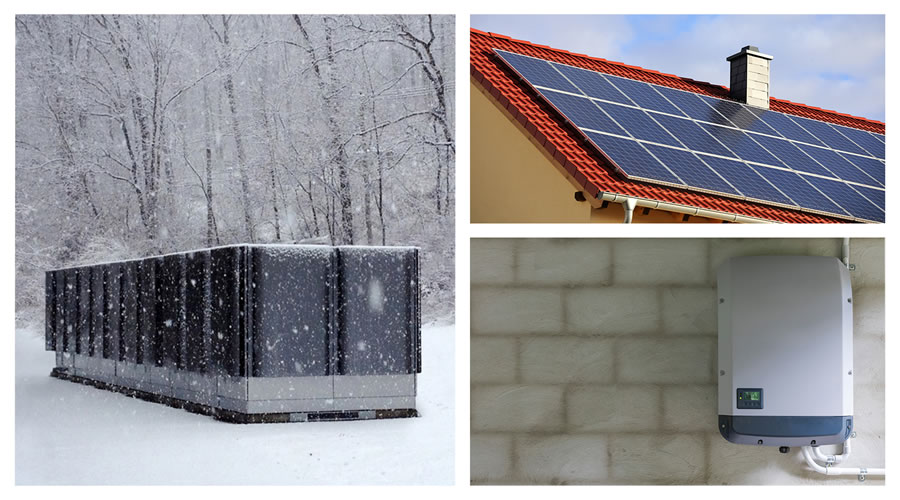

For many years, large corporations have envisioned microgrids as an ideal solution to ride through outages. But many of the microgrids available are unappealing; they use polluting diesel generators, which require many gallons of onsite backup fuel, or inefficient gas combustion generators, as their energy backbone. Today, with the emergence of clean, modular, flexible fuel cell microgrids, which can deliver powerful new operational, environmental, and financial benefits, microgrids are becoming a commercial reality and gaining traction.

Read Electricity in a Digitized World: A Perspective from KR Sridhar

Because microgrids create electricity where it’s used, they bypass the need for large transmission networks that send electricity from a power plant over thousands of miles of exposed overhead wires—the main reason utilities cite to turn off power during periods of hot, dry weather and high winds.

Each microgrid type has its own energy sources, technologies, power capacities, and cost.

Fuel Cells

Fuel cells provide an essential, foundational element for any microgrid—a constant 24x7x365 power supply. Because of that, they can work entirely on their own or be integrated with other intermittent sources like solar, hydro, super capacitors, and batteries. In other words, fuel cells provide an ideal platform on which other technologies can ride and offer a complete solution for others.

Fuel cells convert natural gas, biogas, or hydrogen into electricity through an electrochemical process. Depending on size, they can supply an entire facility’s peak load or power just its critical systems, like coolers at grocery stores or lighting and cash registers at big box retailers.

In addition to delivering always-on, resilient power, fuel cells reduce greenhouse gas emissions (by 50 percent compared to the U.S. grid), and unlike gas combustion generators, release virtually no criteria air pollutants. They also offer a high degree of cost predictability, making it possible to lock in long-term power costs instead of facing yearly utility rate uncertainty and increases.

Solar + Batteries

Another microgrid option is combining solar and battery storage that is capable of being “islanded” (most currently cannot) with switches during a power outage. It can be easier to match solar to a facility’s energy needs, but the technical challenge is pairing the intermittent resource—solar doesn’t work at night or when it is cloudy—with the finite storage of batteries, even the largest of which last only several hours, not entire days. Most facilities—and even utilities that have created microgrids this way for remote communities—must pair them with diesel- or natural gas–powered combustion generators.

Diesel

The third option for a microgrid is one of the hardest to implement and maintain: a diesel generator paired with renewables. In California and other environmentally conscious states, it’s incredibly difficult to obtain new permits to run them and for good reason—they emit large amounts of harmful local air pollution.

The fuel needed to operate a generator costs a lot of money, plus generators must be maintained and tested monthly, and they often don’t start when an emergency does occur. There’s also the issue of getting fuel during a multiday blackout, when hospitals and first responders get priority to that fuel. In places like New England, where winter storms have knocked power out for a week or more, fuel delivery trucks often can’t make deliveries because of unplowed or blocked roadways.

In California, there’s often a monthly cap on how many hours a business can run a diesel generator; 50 hours for some facilities is not nearly enough in today’s “new normal” of multiday power outages. If, like grocery chains and big box stores, a business runs thousands of facilities, the operational challenges (including obtaining enough reserve fuel) are exponential.

Microgrids: Addressing today’s new normal

Mixed-resource microgrids can take up to two years for regulators and utilities to review and approve, says Mike Gravely, team lead for the California Energy Commission’s (CEC) energy R&D division. The CEC has helped fund and provide expertise for several mixed-source microgrids, including those at three Fremont fire stations, Kaiser Permanente’s Richmond Medical Center, and Blue Lake Rancheria, a tribal community in Humboldt County.

“Right now every microgrid is different and built for different uses, and that makes it harder to get them through the technical and regulatory process,” says Gravely. “So as we go forward, what we’re trying to do is work with the utilities and the PUC [Public Utilities Commission] on other possibilities like making more modular systems and helping them develop standards.”

Bespoke microgrids built with existing onsite energy sources like solar, diesel generators, and batteries face numerous challenges. Existing power sources must be retrofitted into a microgrid and must rely on third-party computer control systems to switch seamlessly from the main utility grid to the microgrid during a power outage. These require customized, therefore expensive, configurations.

However, modular fuel cell microgrids that are deployed at commercial and industrial facilities largely bypass these problems. “If you’re a commercial player, you could have 50 similar stores throughout the U.S.,” Asmus says. “So you deploy one and then go, ‘Wow, I love it.’ And because you have a huge portfolio, you can replicate and finance them easier.”

With fuel cells providing an always-on, reliable energy foundation, businesses can also add intermittent resources like solar, wind, and hydro without worrying about tapping the grid for power on cloudy or windless days. In the case of Bloom’s modular fuel cell units, a company can always add more energy capacity as its business and its energy needs grow.

Says Asmus: The scalability of the approach allows investors to “feel more comfortable.”

“If you’re a commercial player, you could have 50 similar stores throughout the U.S. So you deploy one and then go, ‘Wow, I love it.’ And because you have a huge portfolio, you can replicate and finance them easier.”

That explains the journey to microgrid adoption by Northeast grocery chain Stop & Shop. In 2014 and 2015, the grocery giant adopted Bloom’s microgrids at two locations, in part to meet its Better Neighbor Promise to reduce its carbon footprint by 20%.

A couple of years later, when a record snowstorm hit the Northeast, the company’s fuel cell–powered locations were among the few grocery stores to remain open. That allowed Stop & Shop to not only serve the public but also spare itself from having to throw away hundreds of thousands of dollars in meats, produce, and dairy, as grocers are required to toss out perishables after four hours without power. Even stores with diesel generator backups couldn’t stay open because their fuel supply ran out and delivery trucks couldn’t get through the snow.

Stop & Shop realized its fuel cells were supplying not just low carbon power, but weather resiliency. It then placed an order to provision 40 more stores with Bloom’s microgrids.

Resilience shouldn’t come at the expense of clean energy goals

Fuel sources in microgrids range from zero emissions to low emissions to diesel, with diesel being one of the dirtiest and most common fuels used for backup generators. Experts see the latter as counterproductive to the overall carbon reduction goals of local regions and nation states.

“We have three bills coming due,” says Alexandra von Meier, an adjunct professor of electrical engineering at UC Berkeley and director of the California Institute for Energy and Environment’s Electric Grid Program. “The first is the damage from climate change. The second is making investments in energy resilience in the face of climate change. The third is preventing further climate change from happening. So if we’re going to spend billions of dollars, let’s spend it in a way that meets more than one of these goals.”